Most candidates were able to:

- state the safety rules to be observed in a workshop;

- list the types of machines used in a wood workshop.

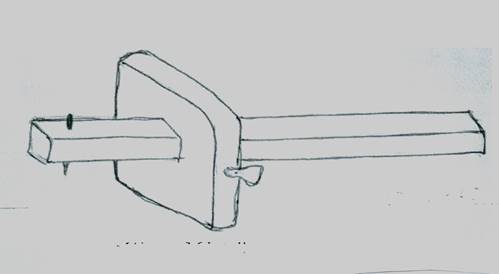

However, they were unable to sketch the marking gauge correctly.

They expected response to question 6 is as given below:

- Safety rules in workshop

- walk do not run;

- always wear safety boot;

- wear helmet;

- remove protruding nails from temporary work immediately after dismantling;

- long pieces of timber should be carried by two persons;

- always put on a safety belt while on roof top;

- store inflammable liquid in seal container away from heat or flame;

- store tools and equipment properly;

- maintain a balance position while using a saw;

- wash hand before and after work;

- close vice when not in use;

- keep work bench tidy;

- in case of accident inform the instructor immediately;

- be sure unused tools are properly kept in the shelves;

- be sure all machines are switched off after used;

- wear goggles while using a sawing machine.

-

- Machines used in wood workshop:

- wood lathe;

- mortise;

- band saw;

- cross-cutting machine or radial arm saw;

- circular saw bench;

- surface planer;

- thicknesser machine;

- dimension machine;

- sanding machine;

- tenoning machine;

- spindle moulder;

- mortising machine.

|