Question 2

(a) List three heat treatment processes

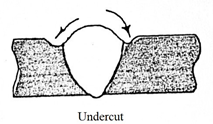

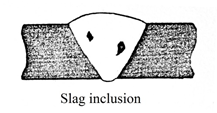

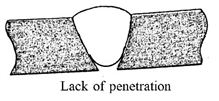

(b) With the aid of sketches, show the following weld defects:

(i) undercut;

(ii) slag inclusion;

(iii) lack of penetration.

(c) State one cause of each of the weld defects in 2(b).

Observation

Part (a) posed no difficulty to the candidates. However, most of the candidates could not sketch the weld defects neatly and correctly. The required responses are as given below.

(a) Heat treatment processes

- Annealing

- Normalising

- Tempering

- Hardening

- Case hardening/carburizing.

(b) (i)

(ii)

(iii)

(c) (i) Undercut can be caused by

- too high current;

- too large nozzle;

- too long arc length;

- too rapid welding speed;

- insufficient filler metal;

- poor manipulation of blowpipe;

- wrong angle of blowpipe/electrode.

(ii) Slag inclusion can be caused by

- too narrow included angle of joint;

- high viscosity of molten metal;

- rapid chilling of molten metal;

- too low weld temperature;

- unclean metal surface/joint;

- poor manipulation of blowpipe/electrode;

- use of damp electrode;

- too rapid welding speed.

(iii) Lack of penetration may be caused by

- faulty joint design

- too rapid welding speed;

- insufficient welding current;

- too large electrode/filler rod;

- insufficient filler metal;

- poor manipulation of blowpipe/electrode.