Question 2

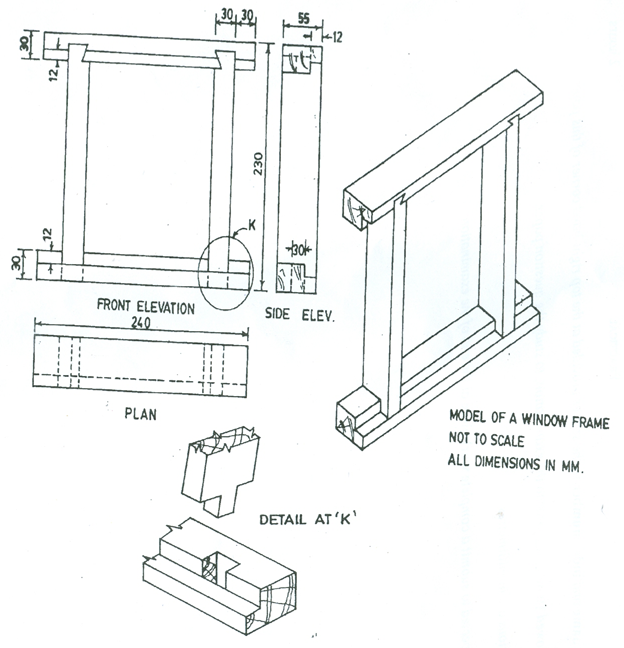

- Produce the test piece shown below, using timber which has been planed to the following sizes:

Three pieces - 30 x 60 x 300}hardwood

One piece - 30 x 60 x 150}hardwood

Observation

PROCEDURE STEP BY STEP

STEP 1

Candidates were required to make through haunched mortise and tenon joint for the part of a window sash. Few candidates were able to make the joint correctly. However, some of them could not make the joint correctly as required.

Each candidates workpiece was to have one mortise at the top rail of the sash with tenon at the stile of the sash fitted together without splitting.

STEP 2

Candidates were required to make stopped mortise and tenon joint for the model of a window sash. Some candidates were able to make the joint correctly. However, most of them could not make the joint correctly as required.

Each candidates workpiece was to have two mortises at the top rail and middle rail of the sash with tenons at the two ends of the muntin fitted together without splitting.

STEP 3

Candidates were required to make through mortise and tenon joint for the part of a window sash. Most candidates were able to make the joint correctly. However, some of them could not make the joint correctly as required.

Each candidates workpiece was to have through mortise at the left stile of the window sash with tenon at the middle rail of the sash fitted together without splitting.

STEP 4

Candidates were required to chamfer the top rail, middle rail, stile and the muntin of the window sash from end to end. Majority of candidates were able to chamfer the top rail, middle rail, stile and the muntin of the window sash from end to end. However, some of them failed to chamfer the top rail, middle rail, stile and the muntin of the window sash from end to end. Each candidate’s workpiece was to chamfer the top rail, middle rail, stile and the muntin of the window sash from end to end.

STEP 5

Candidates were required to assemble their workpiece correctly and clean up. Few candidates were able to assemble their final workpieces correctly. However, most of them were unable to assemble their final workpieces correctly.

Each candidate’s final workpiece must be well assembled and have a smooth surfaces.